TOILETOWA

Saitama、Japan 2023

Concept

All beings are born from the earth,

and return to the earth in a circle.

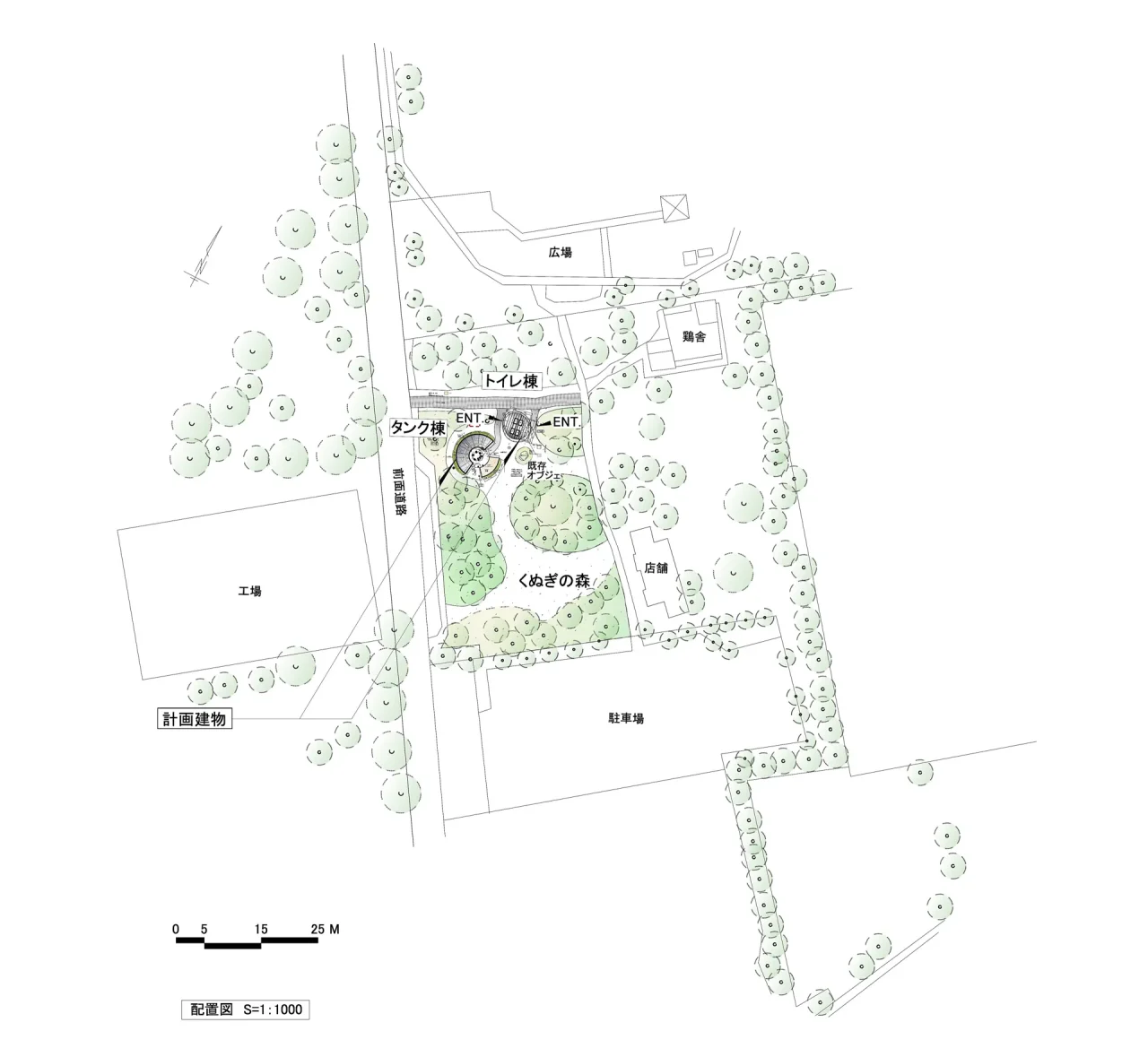

TOILETOWA is an architecture of circulation and regeneration that makes this visible. More than just a toilet, it was built as an environmental education space attached to the headquarters of Ishizaka Corp in Oak Forest, which recycles industrial waste and serves as a model for a future waste-free, recycling-oriented society.

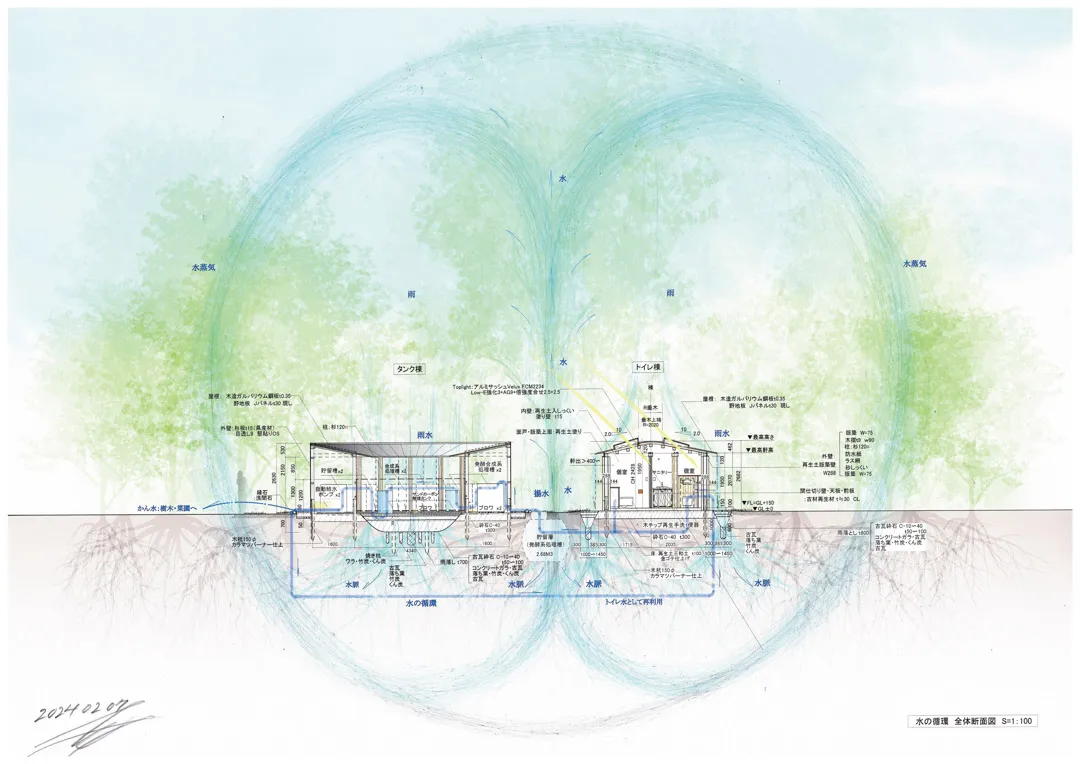

It is a wooden building consisting of a toilet building with a circular rammed earth wall made of recycled soil NS-10 developed by Ishizaka Corp,, and a tank building that shows the process of perfect recycling and circulating wastewater by combined fermentation of microorganisms.

To reduce the environmental impact, the foundation is made of crushed stone instead of concrete. – Made using wooden stakes. With the theme of recycling in the materials used, the interior walls and earthern floors of the toilet building are made of almost recycled materials of soil, wood, and glass. The hand wash and toilet bowls are also made of recycled wood chips.

Toilet wastewater is not only completely recycled and reused but also used as agricultural water to promote the growth of surrounding garden crops. Furthermore, by using natural materials around the building to “regenerate the earth” and allowing water and air to pass through the soil from the ground, the forest in the area has been regenerated, creating a refreshing air and atmosphere. The wooden construction was hand-carved by young carpenters, making use of plastering techniques such as rammed earth, plastered walls, hard-packed earthern floor, and mortar polishing counter, and not only the materials but also the circulation of traditional architectural techniques of wood and clay.

______ Photo, takeshi noguchi

Drawings, Tono Mirai architects

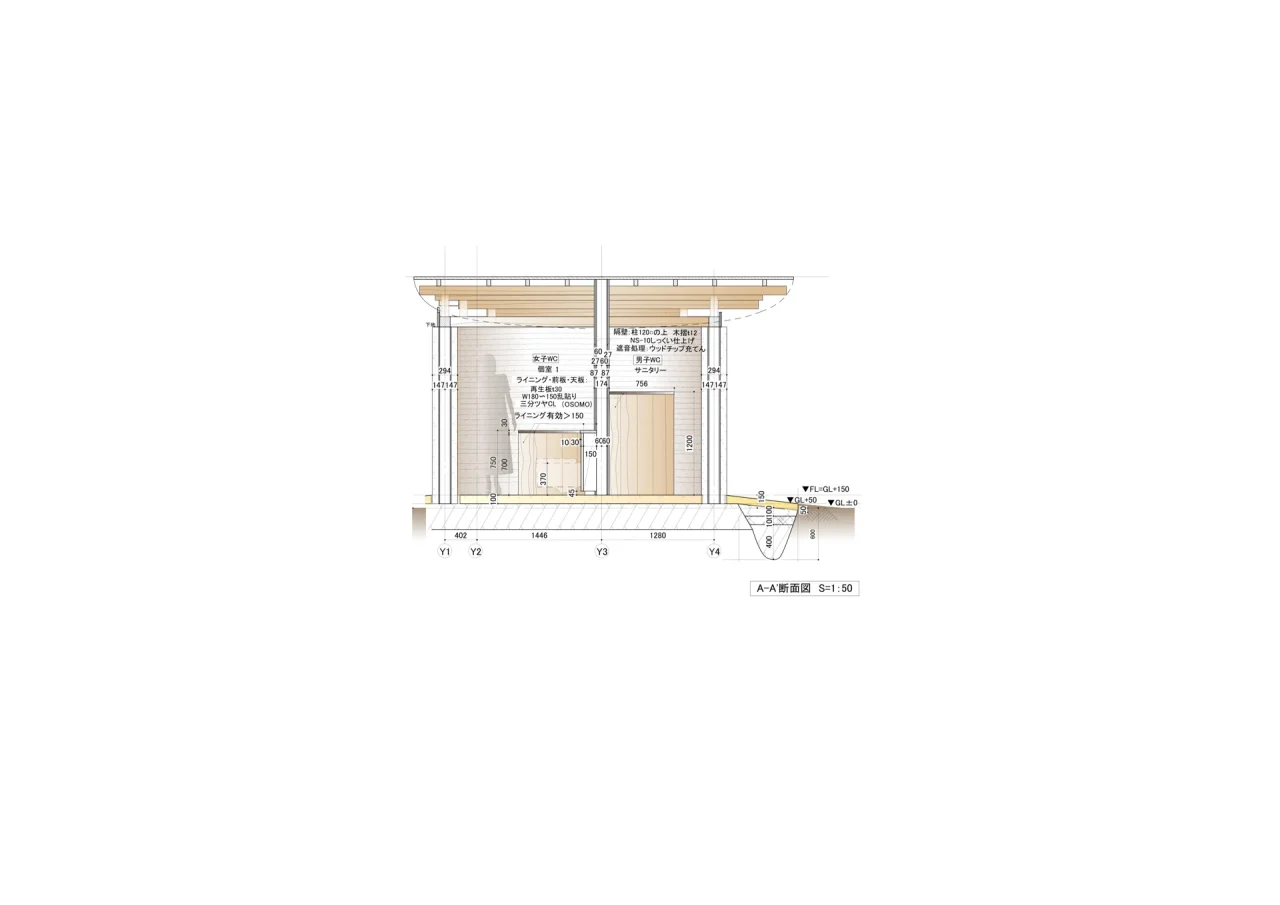

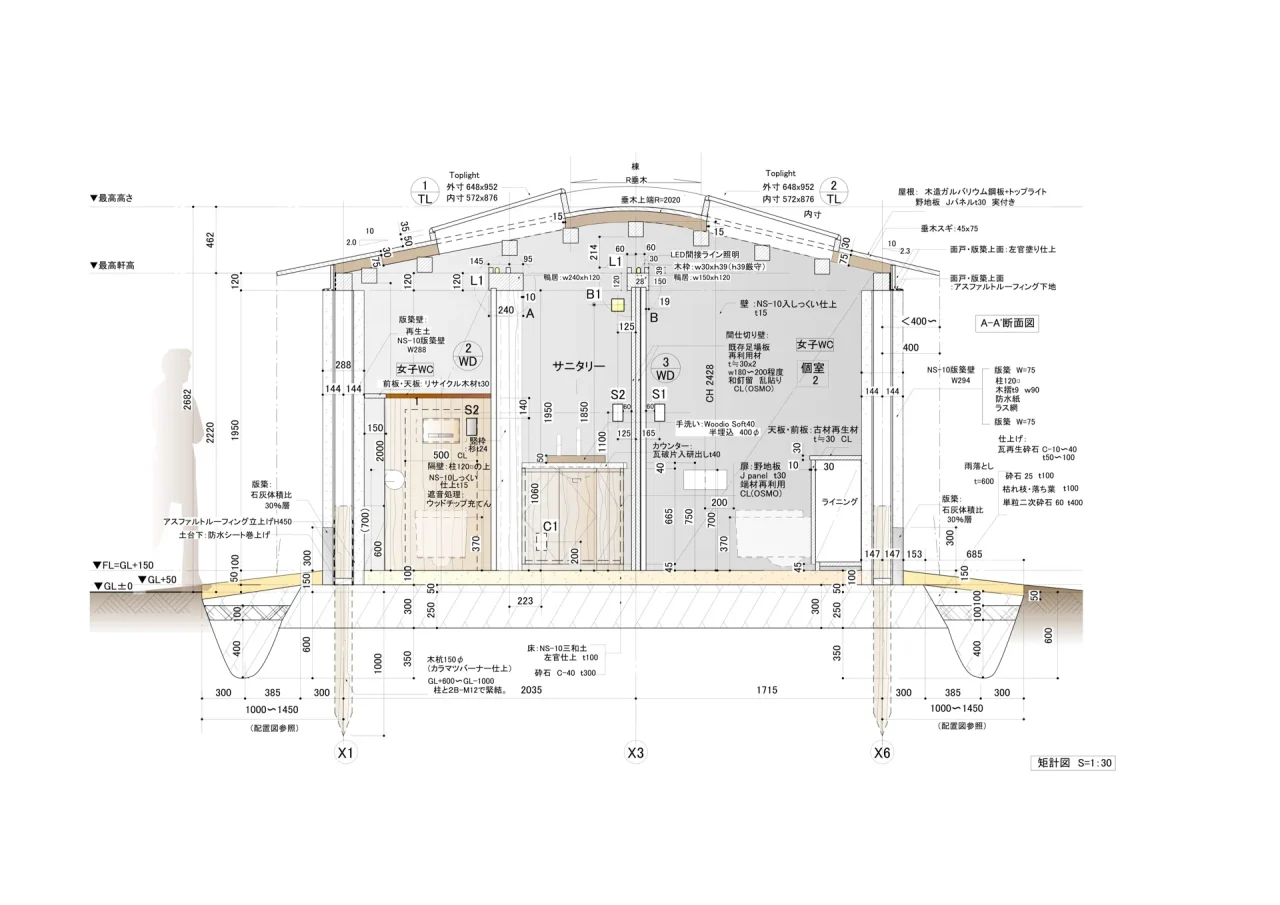

Toilet Building

Architecture that expresses the ecosystemic cycle of water and air,

together with materials and craftsmanship.

The structure is crafted predominantly from materials that either “return to the earth” or are recycled, avoiding the use of concrete.

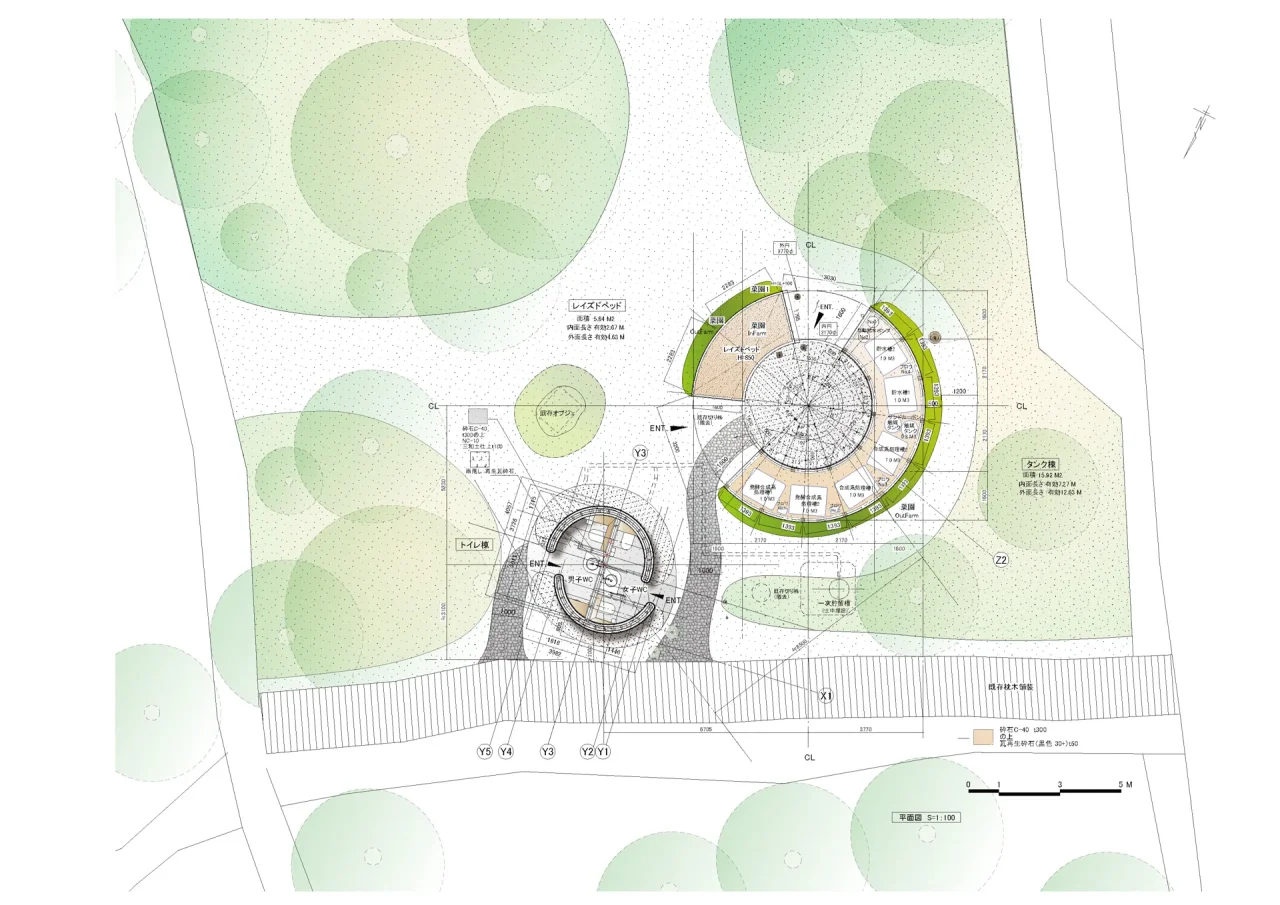

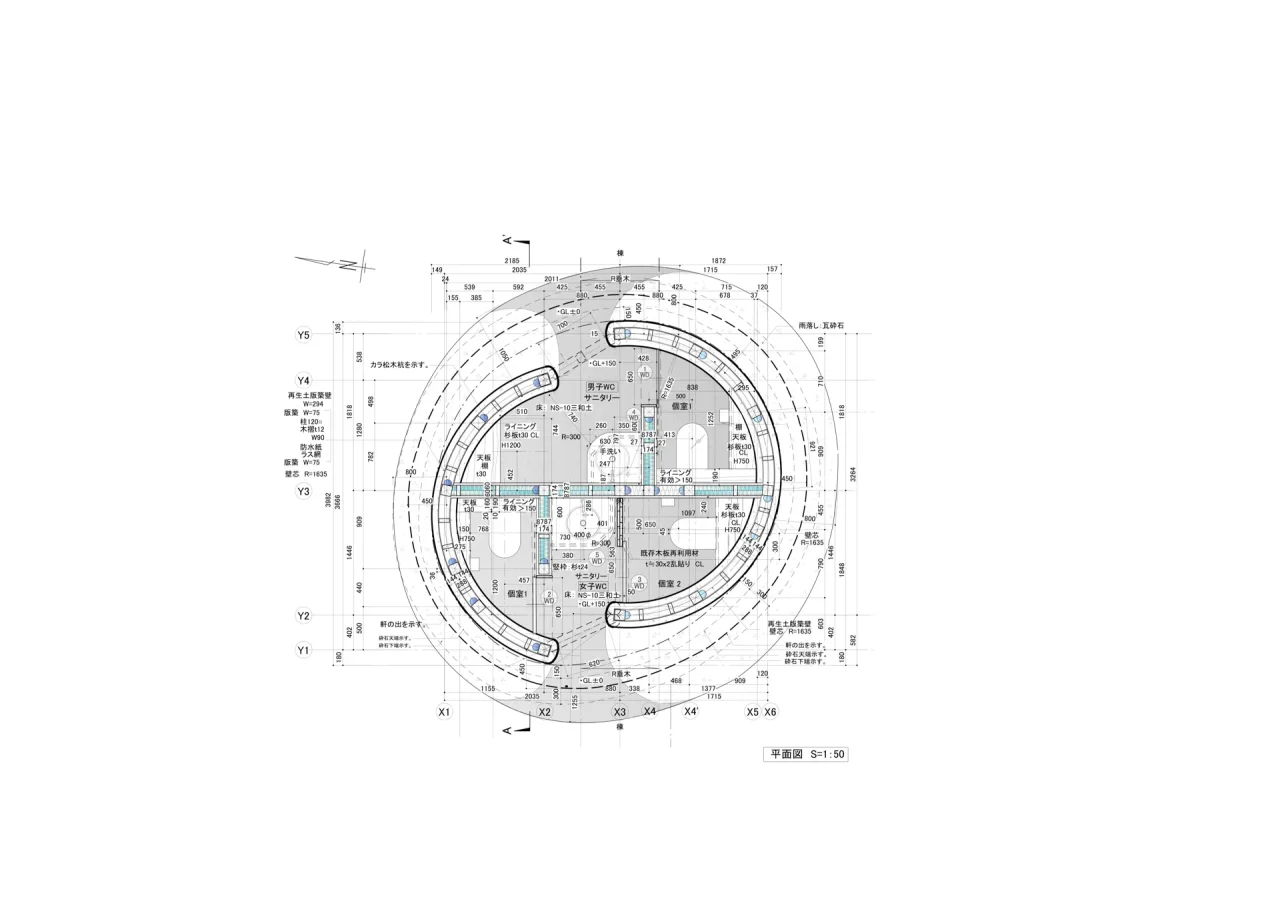

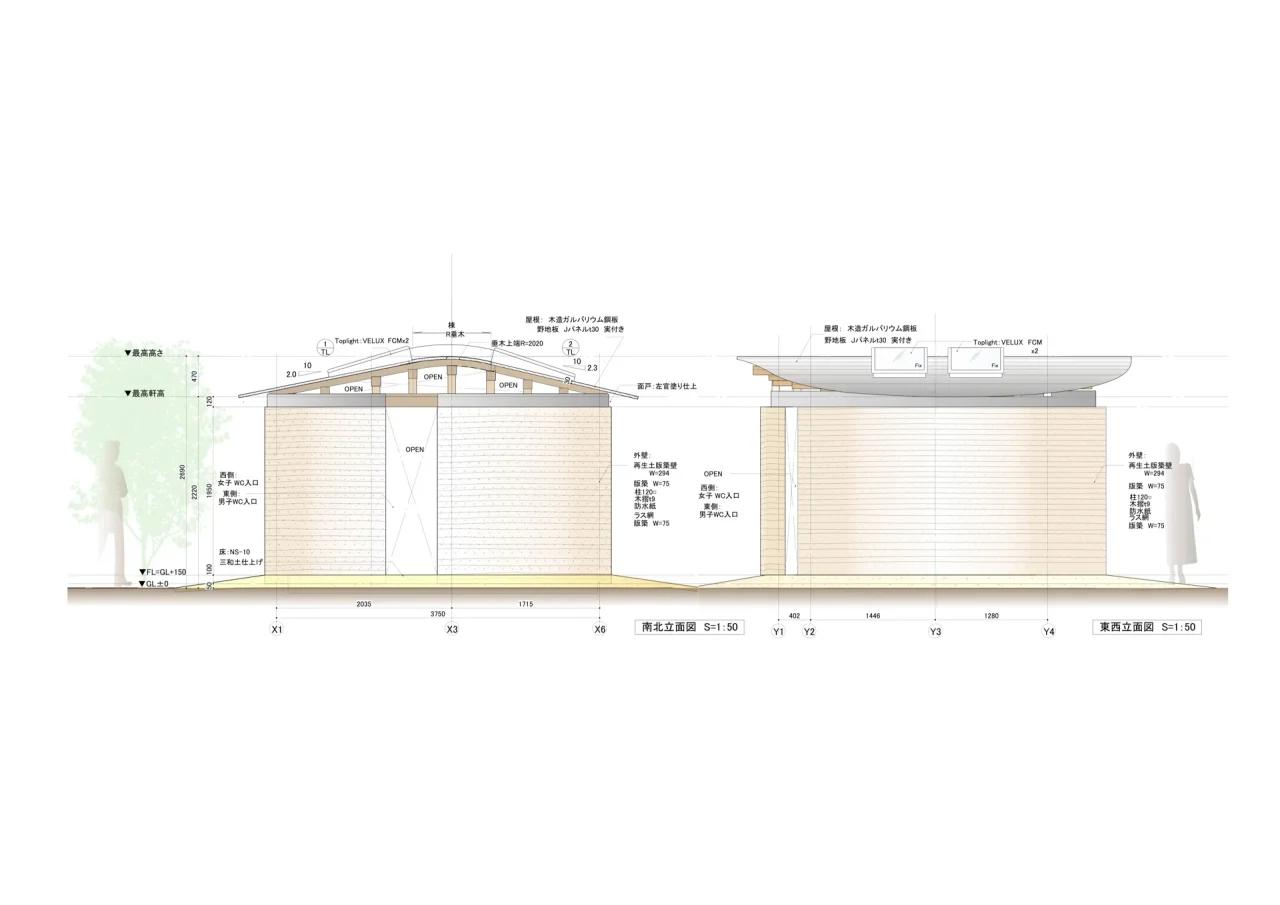

Two semicircular rammed-earth walls, composed of repurposed soil and placed in staggered formation, create a gentle movement and a sense of circulation within the forest setting. With light streaming in from skylights, the entire building acts as a “well of light,” connecting the sky and the earth.

The primary material used, NS-10, is a recycled soil developed in collaboration by the building owner, Ishizaka Sangyo, and IS Engineering. Derived from the deconstructed gypsum boards and soil mixtures from housing materials brought to Ishizaka’s facilities, this material is sorted and refined at the company’s factory. Previously, it was used solely as a paving subgrade material, but in this project, it was innovatively employed as a construction material.

Due to limited compressive strength, the recycled soil was not used independently as rammed-earth structure; instead, it was incorporated as a finish around a timber frame, with slaked lime mixed in and compacted to form inner and outer rammed-earth walls, each 75mm thick, resulting in a combined 294mm thickness. Further, slaked lime was mixed with the soil to create traditional *sanwa-do* floors and applied as plaster mixed with slaked lime for interior partition walls, testing the full potential of this recycled soil.

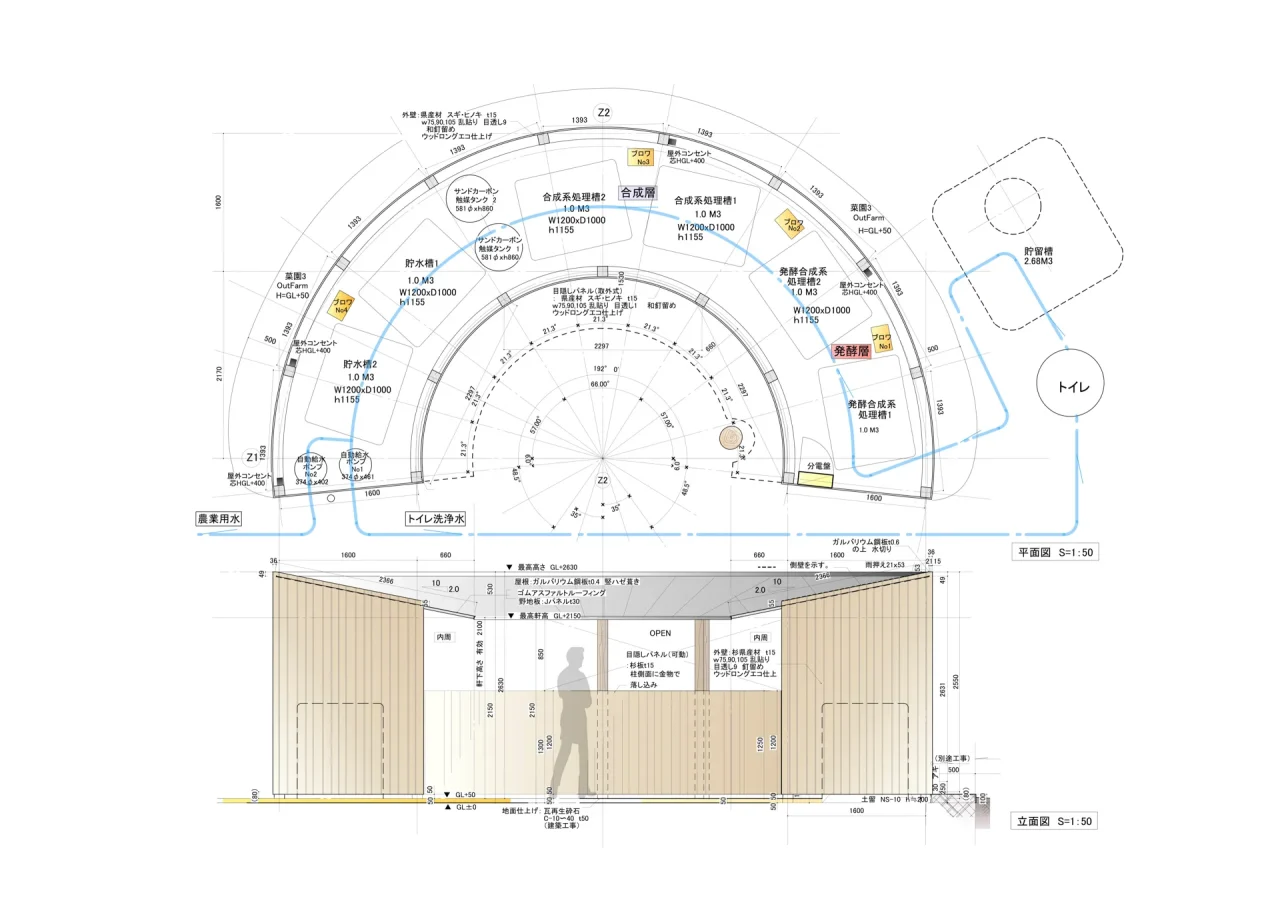

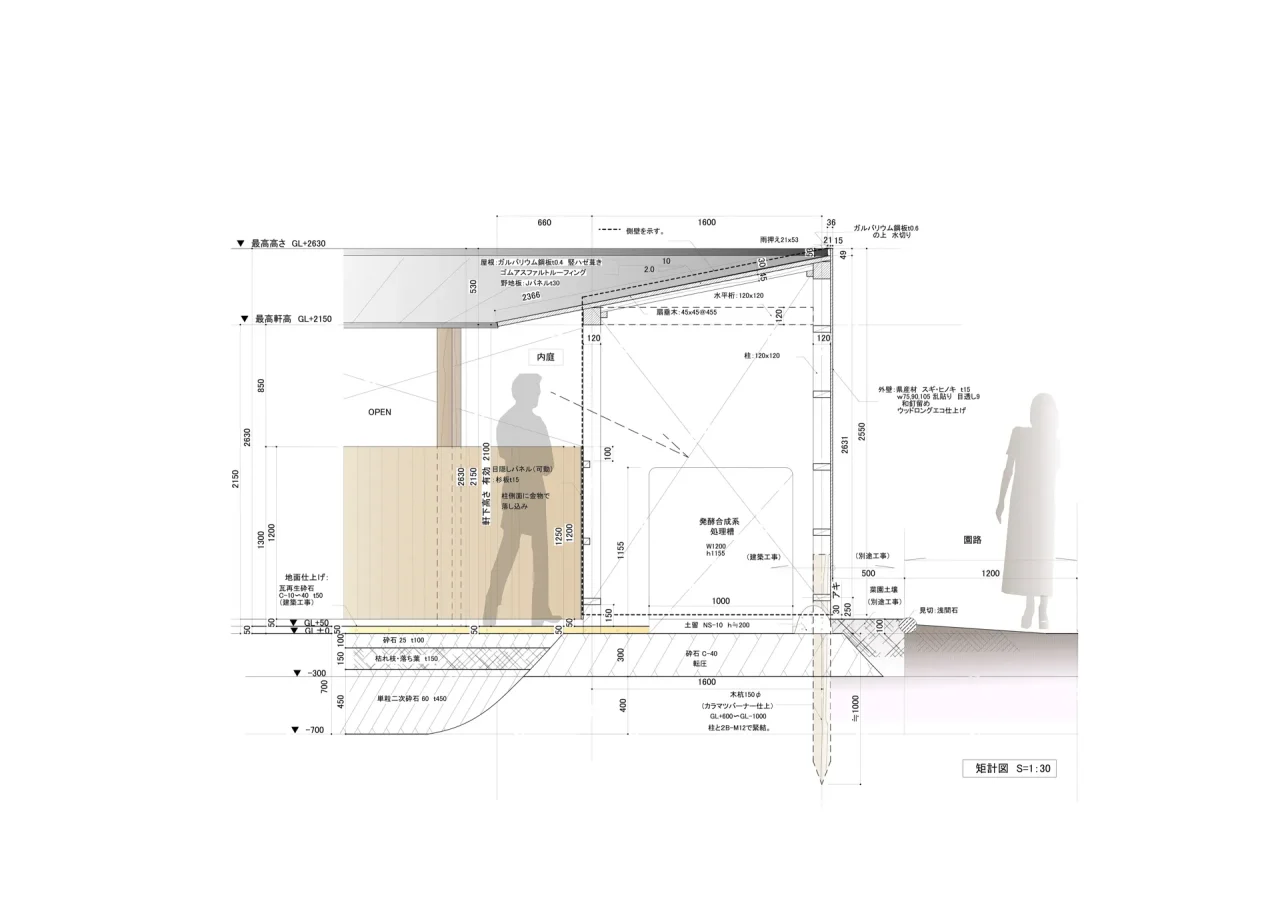

Tank Building

Cobined fermentation has been used in Japan for over 20 years, and here we aim to show the mechanism of water circulation in a sophisticated design as a showcase for the recycling society of the 21st century.

While retaining the existing trees, the complex fermentation process of the fermentation layer, synthesis layer, and catalyst tank is arranged in an arc, expressing the circulation of water with raised beds (three-dimensional vegetable garden) facing a circular courtyard.

In order to keep the overall scale down, the roof has a 2/10 slope on the courtyard side, and the tank can be seen by removing the blind door. The exterior wall is inspired by Local landscape of the forest(Musashino’s Satoyama), and is made of prefecture-produced cedar boards of different widths pasted randomly.

Wood Long Eco, a wood protectant derived from natural materials, is applied to each piece, and each piece changes to a different color as it ages with UV rays. Through the gaps between the boards, people can see sunlight filtering through the trees and see the actual forest, creating a landscape that blends in with the forest.

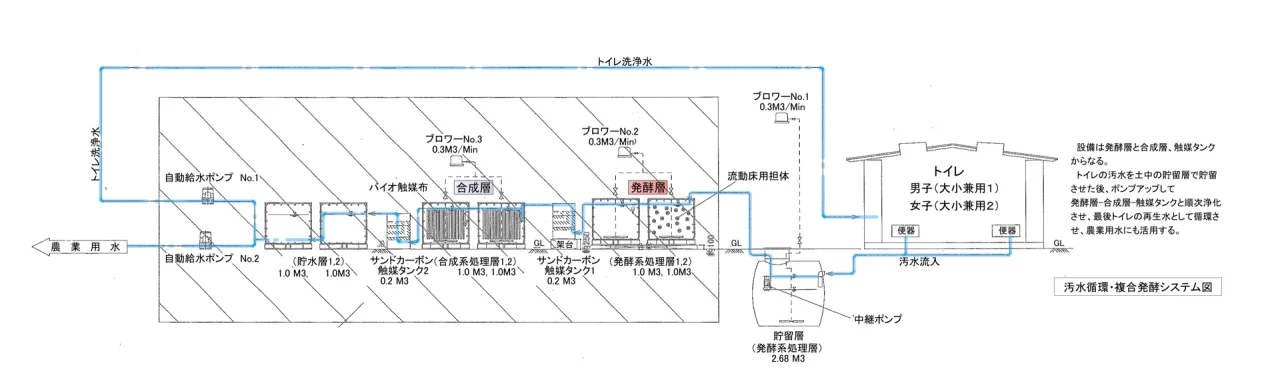

Combined fermentation system

A biotechnology called combined fermentation (EMBC) developed by Dr. Yasuhide Takashima is used to treat and regenerate this toilet wastewater. By allowing aerobic bacteria and anaerobic bacteria to coexist, co-prosperate, and coexist, changes in fermentation, decomposition, fermentation synthesis, and fusion occur, and the water is purified and contains zero bacteria, malignant bacteria, and E. coli, making it odorless. Clear enough to drink. The enzyme water created in this process circulates endlessly, and the water containing enzyme-bound crystals activates the soil and has the effect of improving crop productivity.

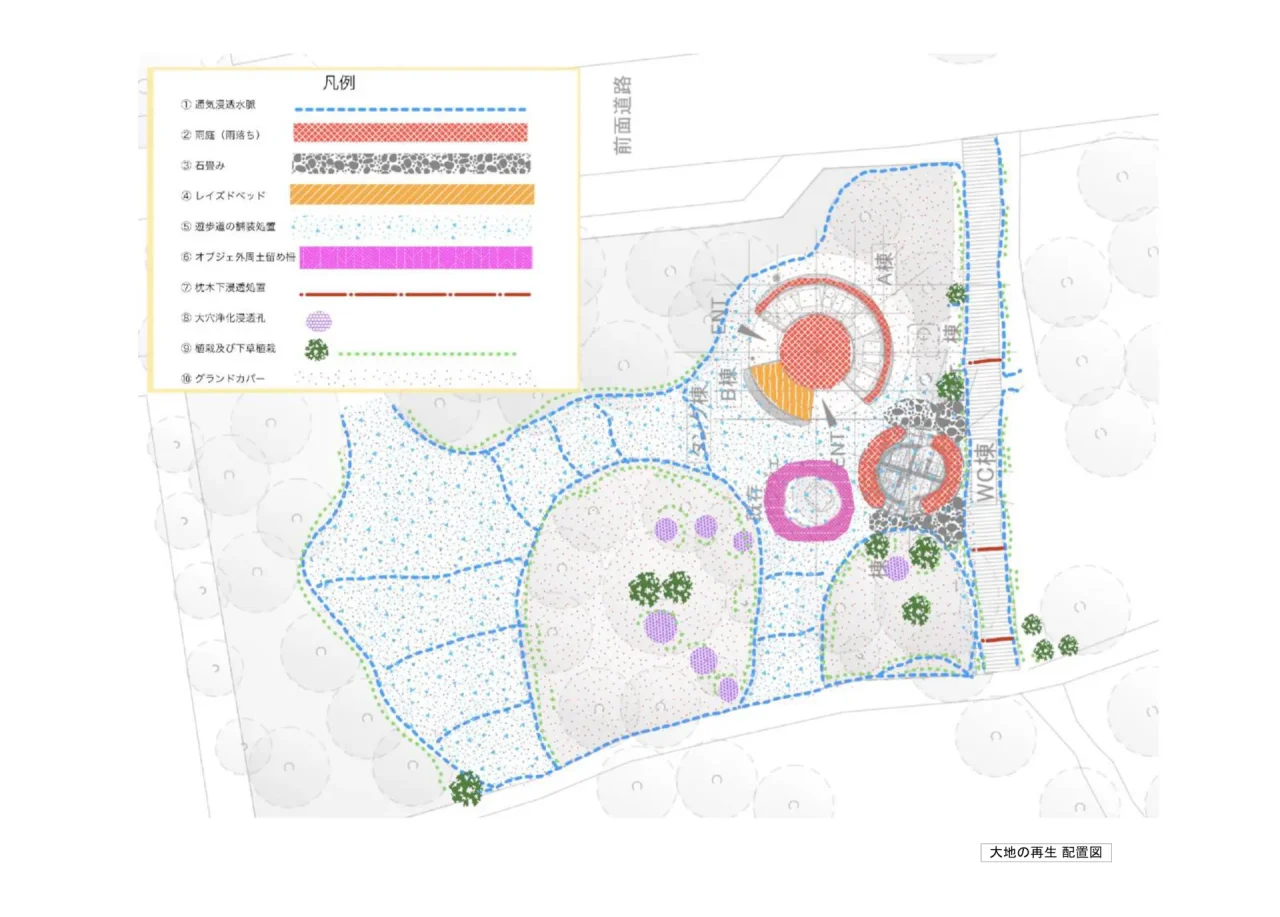

Regeneration of the earth

Along with the construction of this toilet, the surrounding forest and soil were weakening, so WAKUWORKS carried out work to “regenerate the earth” of the forest, centering on the toilet, as part of the work to regenerate the forest along with the exterior maintenance.

Plants and plant-derived materials that can be found on the site, such as tree branches, fallen leaves, bamboo charcoal, and charcoal, are buried vertically and horizontally in the soil to create water veins and air flow underground, which aggregates the soil. It activates the functions of the mycelium, root system, microorganisms, and living organisms in the soil, cultivating the inherent power of the soil.

Recycled crushed stone tiles were used to catch rain, and wood chips and lava stone Asama were used for the sidewalks. Through this work, the soil, which was hard and poorly drained, has been cleared of puddles, and as the trees have regenerated, there has been a refreshing breeze, and it is possible to feel that a circulation of water and air has been created in the forest: earth, wood, architecture, and earth.

Trees are also called “pillars of water,” and they absorb water from the water veins in the soil and emit water vapor from their leaves. Through this earth regeneration project, an invisible water cycle between the soil and the air was realized, and the forest ecosystem was regenerated along with the water cycle of the toilet’s complex fermentation.

Media Link

■ TV Programs

NHK WORLD-JAPAN 2024.04.25

New Public Restroom Designs

https://www3.nhk.or.jp/nhkworld/en/shows/2101024/

■ Architectural website in Japan

architecturephoto

https://architecturephoto.net/205035/

TECTURE MAG

https://mag.tecture.jp/product/20231012-100056/

■ International architectural website

ArchDaily

https://www.archdaily.com/1015881/toiletowa-wc-tono-mirai-architects

Archello

https://archello.com/project/toiletowa

gooood

https://www.gooood.cn/toiletowa-by-tono-mirai-architects.htm

WABISABI

https://www.instagram.com/p/DDTTASdsjjC/?img_index=1

dezeen

https://www.dezeen.com/2024/05/03/toiletowa-tono-mirai-architects-japan/

Keywords

Bio toilet / Combined fermentation system / the recycling society / curve / Rammed earth / Sanwa soil / Mortar grinding / Wooden architecture

Project data

Name — TOILETOWA

Location — Miyoshi Town, Saitama Prefecture

Owner — Ishizaka Sangyo Co., Ltd.

Primary Use — Bio-Toilet

Construction Type — New Build

Zoning Area — Urbanization Control Area, Park Facility

Design

Designer — Mirai Tono, Tono Mirai Architects

Facilities — GEN JAPAN, Marunaka Equipment Industry

Supervision — Mirai Tono, Tono Mirai Architects

Name Design — TSDO, Taku Sato

Construction

Construction — Terashima Construction

Facilities — GEN JAPAN, Marunaka Equipment Industry

Exterior — WAKUWORKS

Area

Site Area — Park Facility

Building Area — 9.9㎡

Total Floor Area — 9.9㎡

Building coverage ratio

Maximum Height — 2.68m

Eave Height — 2.22m

Structure

Wooden 1st story

Foundation

Clasher run・Burned wood pile

Term

Design Period — January 2021 to March 2023

Construction Period — March 2023 to August 2023

Finishing Materials

WC Building

Exterior — Recycled Tile Aggregate, Wood Chips, Asama Stone

Flooring — Recycled Soil NS-10 (Ishizaka Sangyo), Traditional Sanwa-do Flooring

Exterior Wall — Recycled Soil NS-10 (Ishizaka Sangyo), Rammed Earth Finish

Roofing — Galvalume Steel Sheet, t0.35 (Yodogawa Steel), Silver-Black Color “Kizashi”

Interior Wall — Recycled Soil NS-10 (Ishizaka Sangyo), Plaster Finish, Reused Wooden Boards

Eaves and Ceiling — J-Panel, t30, Exposed Timber Framework

Openings — Skylight by VELUX, Model FCM

Toilet — Woodio, Wood Block, Color: Polar

Hand Basin — Woodio Soft 40, Color: Polar

Faucet — SANWA AQUAPIA KT0721C

Tank Building

Exterior and Flooring — Recycled Tile Aggregate, Wood Chips, Asama Stone

Interior and Exterior Walls — Saitama Prefecture Cedar Boards, t15, w75/90/105 (supplied by Okabe Lumber Store), Vertical Random Pattern with 9mm Reveals

Wood Protection Finish by Wood Long Eco (Ogawa Kotaro ∞ Yuriko Co.)

Exterior Wall — Recycled Soil NS-10 (Ishizaka Sangyo), Rammed Earth Finish

Roofing — Galvalume Steel Sheet, t0.35 (Yodogawa Steel), Silver-Black Color “Kizashi”

Eaves and Ceiling — J-Panel, t30, Exposed Timber Framework

Fermentation System — Composite Fermentation Equipment (Takashima Development Engineering)